< Previous | Contents | Next >

Section 3

Corrosion Control Means and Corrosion Margins

301. General

Corrosion control means for units are to be provided in accordance with the relevant provisions specified in Pt 3 of Rules for the Classification of Steel Ships and taking design service life, maintenance, corrosive environment, etc. into account.

302. Paint containing aluminium

Paint containing aluminium is not to be used in positions where cargo vapours may accumulate unless it has been shown by appropriate tests that the paint to be used does not increase the incendiary sparking hazard. Tests need not be performed for coatings with less than 10 percent aluminium by weight.

303. Corrosion margin

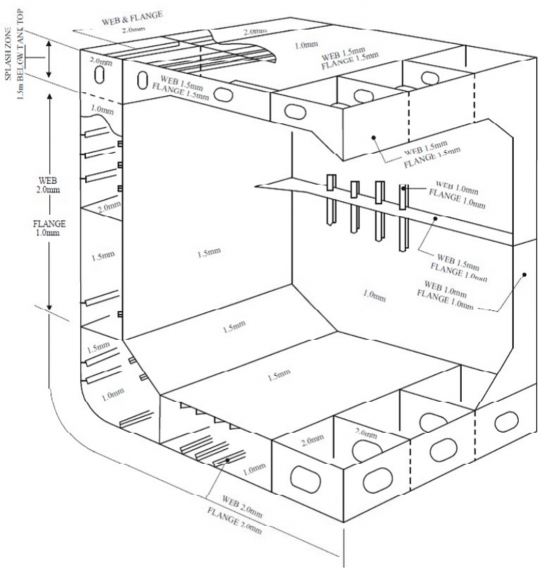

Corrosion margins according to the corrosive environment to which structural members are exposed are to be in accordance with the values given in Table 3.2 and Fig 3.1. In cases where a corro- sive environment is clearly severer than assumed, values that are bigger than the values given in Table 3.2 and Fig 3.1 or additional corrosion control means considered appropriate will be re- quired as deemed necessary by the Society.

Table 3.2 Corrosion Margin

Structural Element/Location | Corrosion Margin(mm) | ||

Cargo Tank | Ballast Tank Effectively Coated | ||

Deck Plating | 1.0 | 2.0 | |

Side Shell Plating | - | 1.5 | |

Bottom Plating | - | 1.0 | |

Inner Bottom Plating | 1.5 | ||

Longitudinal Bulkhead Plating | Between cargo tanks | 1.0 | - |

Other Plating | 1.5 | ||

Transverse Bulkhead Plating | Between cargo tanks | 1.0 | - |

Other Plating | 1.5 | ||

Transverse & Longitudinal Deck Supporting Members | 1.5 | 2.0 | |

Double Bottom Tanks Internals (Stiffeners, Floors and Girders) | - | 2.0 | |

Vertical Stiffeners and Supporting Members Elsewhere | 1.0 | 1.0 | |

Non-vertical Longitudinals/Stiffeners and Supporting Members Elsewhere | 1.5 | 2.0 | |

![]()

Fig 3.1 Corrosion Margin